Air Quality Index (AQI) & your choice of filter

The AQI index is a measure of daily air quality. It determines how polluted or clean the air is, and what health impacts it may bring. The AQI pays attention to health effects experienced within few hours to few days after inhaling polluted air. Environmental Protection Agency (EPA) measures AQI for five mainstream air pollutants as regulated by Clean Air Act, and these are:

1. ground-level ozone

2.particle pollution (also called particulate matter)

3. carbon monoxide

4. sulfur dioxide

5. nitrogen dioxide

Each pollutant has been allotted established national air quality standards by EPA to protect health on a national level. The first two air pollutants mentioned above, are termed as the most dangerous for human health.

AQI – The functioning

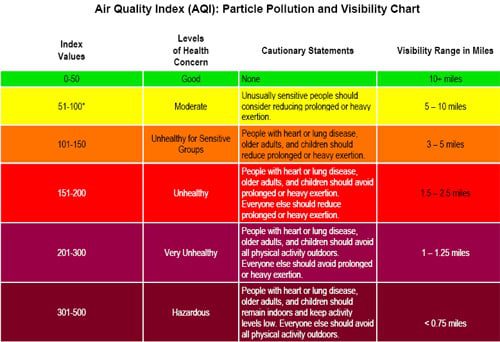

Higher AQI levels imply higher level of air pollution, and thus greater health concerns. For instance, AQI value of 50 shows fine air quality with negligible potential to impact public health, while value of 300 and above shows hazardous air quality. An AQI value of 100 usually coincides with national air quality standard for pollutants which has been set by EPA. The value below 100 are termed as satisfactory, while above ones show unhealthy air quality, firstly for sensitive people groups, and then for everyone, as the value increases.

Understanding the AQI

AQI keeps you informed regarding what local air quality is there and how it affects health. To make it easily understandable, AQI has been divided into six classes. EPA has assigned a certain color to each class for understanding pollution level.

IAQ & Air Filters

Since higher IAQ index means higher pollutant level, you would want the air filters having high efficiency to remove pollutants from the air and give as low IAQ index reading as possible. In this regard, high efficiency air filters include HEPA filters, which have also been recognized by EPA as the best product for having airborne particles free environment and low IAQ index reading. HEPA filters are able to filter the air at a very fine degree, blocking particulates that are 0.3 microns or bigger. HEPA filters can easily catch 99.97 percent of airborne pollutants, leading to low and well maintained IAQ index and lesser health concerns.